Thermo Compression Bonding, often known as TCB, is a method that involves the use of heat and pressure in order to bond two or more different materials together. The process of bonding one material to another entails first applying heat to a substance that is either metallic or plastic, and then applying pressure to the material after it has been heated. The application of TCB may be found in many different sectors, including those dealing with electronics, medical equipment, automobiles, and aircraft.

In recent years, there has been a growth in the use of TCB as a result of the several benefits it provides, some of which include the capacity to bind a broad variety of materials, high bond strengths, and consistent bonding quality. Additionally, since TCB may connect materials of varying thicknesses, it is a preferred option for high-volume production operations because it can be accomplished rapidly and effectively.

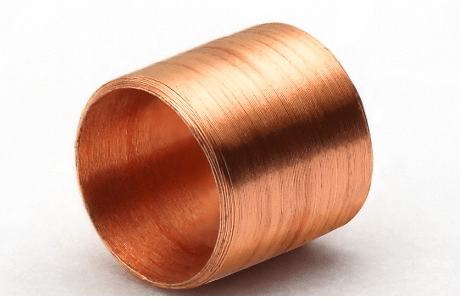

Often used in printed circuit boards

When Thermo compression bonding electrical components to printed circuit boards, TCB is a technique that is often used in the electronics industry. Examples of such components include integrated circuits. In the field of medical technology, TCB bonds different components of medical devices, such as surgical tools, diagnostic equipment, and implanted devices. TCB binds structural components in the automotive industry as well as the aerospace industry. These components include engine components and aircraft wing components.

A further benefit of TCB is that it is capable of producing high-strength bonds that are not only long-lasting but also resistant to the effects of external conditions such as fluctuations in temperature and humidity as well as vibration. Because of this, it is well suited for use in applications that are very demanding, such as those found in the aerospace and automotive sectors, where components must be able to survive particularly harsh conditions.

Extremely scalable

TCB is not only adaptable, but it is also extremely scalable, which means that it may use in manufacturing processes that conduct on both a small and a big scale. This enables producers to attain high levels of consistency and quality, even in large-volume manufacturing runs, which is a significant competitive advantage.

It is an adaptable and dependable method that is gaining relevance in a wide range of sectors because to its versatility and dependability. Because of its versatility in terms of the materials it can join, the high strength of the bonds it creates, the quality it maintains throughout, and the cost-effectiveness of using it, it is an alternative that is appealing to producers in a broad variety of sectors. It expects that TCB technology will continue to see developments in the next years, which will lead to an increase in the application of the technology.

Conclusion

In conclusion, Thermo compression bonding is a procedure that is not only clean but also kind to the environment since it does not result in the production of harmful waste, odors, or emissions. Because of this, it is an excellent option for use in applications within sectors that are subject to environmental laws, such as the industries of electronics and medical devices.