If you’re starting a business that revolves around selling a product of your own design, then you are either going to need to manufacture it yourself or have someone manufacture it for you. The latter option might be easier to start, but the former offers more control and, providing it is done right, could be more cost-effective in the end. However, you’re going to need to set up your own production line. Do you know what it takes to do that?

The right space

First of all, you have to make sure that you’re able to find the space that meets your needs in terms of room and suitability. Regular office space isn’t going to cut it, but sites like Shopspace4Rent can help you find the industrial space that is suited for you. Buildings that have worked as factories, warehouses, or even garages in the past are more likely to fit your needs.

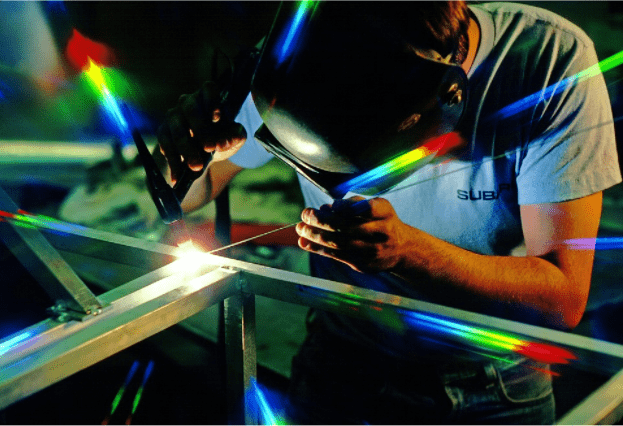

The right machines

Of course, you’re going to need the tools that can help you get the production line up and running at the same time. To that end, you need to think carefully about how you construct your products, and which machinery you might need for them. Then, find the machinery suppliers that can not only provide the products but help you take the best care of them possible, too. It’s often better to do directly to the manufacturers than buying through a middleman that might not easily be able to help you keep in stock of replacement parts.

The right power

The machines that you use are going to take considerable power. It might not be the most efficient to try and rely on a direct power supply from the mains but to instead look at industrial power options from teams like Volvo Penta. Making sure that you have backup power so that you can keep working in the event of a blackout or brownout is important, too.

The right team

While more and more manufacturing labor is being automated, that doesn’t mean that you can skip out on hiring the right people to man the machines that are doing all of the work, as well. Aside from line workers, you’re going to need managers, health and safety officers, and and those with the skills to keep the machines up and working (though some of these skills can be trained into line workers with the right investment.)

The right suppliers

Lastly, you need to make sure that you find the right suppliers for the raw materials that are going to be turned into the products that you create. Who is the best supplier will depend on factors like your location, the stability of their supply chain, and which materials, exactly, they are providing. But there are sites like Raw Materials Suppliers that can help you find the suppliers that best meet your needs.

It is not cheap to set up a production line, not even for a small one. Make sure that you have the capital you need to get things up and running as soon as you need to.