Business effectiveness has become synonymous with precision, and at the heart of this transformation are precision equipment companies whose cutting-edge technology and innovations are revolutionizing industries worldwide. These businesses provide the tools and support necessary to improve performance, increase quality, and drive efficiency in the highly competitive marketplace. Their impact on business performance cannot be overstated, as they enable companies to achieve and maintain a competitive edge in today’s rapidly evolving market landscapes.

Increased Efficiency Through Automation

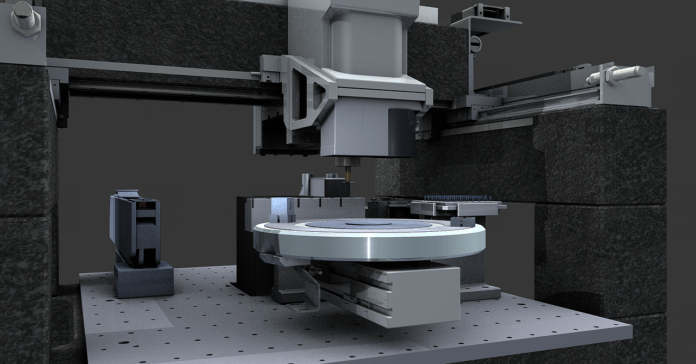

One of the key avenues through which precision equipment companies enhance business performance is facilitating the integration of automation solutions. Automation, driven by sophisticated technologies provided by nabtescomotioncontrol.com/en/, not only streamlines production processes but also minimizes human error, leading to more consistent and higher-quality outcomes. This shift towards automation allows businesses to repurpose human resources to more strategic roles, optimizing workforce capabilities and boosting efficiency.

Additionally, the data collected from automated processes offers invaluable insights into operational efficiencies and areas for improvement, enabling data-driven decision-making. Furthermore, automation contributes to sustainability by reducing waste and energy consumption and aligning business operations with environmental goals. Thus, the role of precision equipment companies in ushering in a new era of automated efficiency is pivotal for businesses aiming to thrive in the modern marketplace.

Enhanced Accuracy and Consistency

Using precision equipment significantly enhances accuracy and consistency in production and service sectors. This precision is crucial for industries where even minor errors can lead to major defects or failures. For instance, precision equipment technology is indispensable in electronics, aerospace, or medical device manufacturing due to minimal error margins.

Precision tools go beyond manufacturing to boost data analysis reliability in tech. Accurate data is vital for algorithm training and decision-making. Businesses using this accuracy ensure top product quality, building customer trust and loyalty. This cycle of precision, quality, and trust elevates brand reputation and sets companies up for long-term success in competitive markets.

Cost Savings and Waste Reduction

The financial implications of incorporating precision equipment into business operations are profound, leading directly to cost savings and significant waste reduction. By minimizing material wastage and optimizing production processes, companies can achieve a more streamlined, cost-effective operation. Precision tools and machinery reduce the need for rework and corrections, lowering labor costs and decreasing production time.

The precise technologies used lead to more efficient resource utilization, reducing excess consumption and promoting sustainability. Investing in high-quality precision equipment pays off over time, cutting operational costs and boosting productivity. This adoption improves a company’s environmental stance and enhances its financial performance, a smart investment for forward-thinking businesses.

Improved Product and Service Quality

The integration of precision equipment in business operations directly impacts the quality of products and services offered. The advanced technology provided by precision equipment companies allows for tighter tolerances, leading to higher accuracy, consistency, and quality control. These factors are especially critical in industries such as medical or aerospace, where safety and reliability are paramount.

With the rise of consumer expectations, businesses must maintain high-quality standards to stay competitive. The use of precision equipment not only ensures superior products and services but also allows for scalability and adaptability to evolving market demands. With precise tools, companies can quickly pivot to meet changing customer needs and preferences, cementing their position as leaders in their respective industries.

Facilitation of Innovation and Product Development

Innovation is key to maintaining competitiveness and market relevance in the modern business landscape. Precision equipment companies are crucial in facilitating this innovation, particularly product development. The advanced technologies and tools they provide enable businesses to explore new ideas, improve existing products, and develop new offerings with unprecedented detail and efficiency.

The ability to prototype and test with high precision accelerates innovation, reducing time-to-market for new products and allowing companies to adapt swiftly to emerging trends and customer demands. This dynamic approach to product development, powered by precision equipment, sets businesses on a path of continuous improvement and growth, fostering an environment where innovation thrives.

Strengthened Supply Chain Management

The impact of precision equipment companies extends beyond production efficiency and product quality; they also play a critical role in strengthening supply chain management. By improving the accuracy and speed of production processes, these technologies enable more reliable forecasting and inventory management, reducing lead times and minimizing stockouts or excess inventory.

Enhanced data collection and analysis improve decision-making and supply chain optimization, ensuring efficient resource allocation and seamless product flow from manufacture to market. This streamlined supply chain cuts costs and enhances customer satisfaction through the timely delivery of high-quality products. Precision equipment in supply chain management is crucial in mitigating far-reaching disruptions.

The symbiotic relationship between precision equipment companies and businesses is vital for society’s economic and technological progress. Companies can survive and thrive in an increasingly competitive environment by recognizing and harnessing the benefits of precision engineering. The message for businesses looking to the future is clear: To achieve operational excellence, precision equipment companies are vital partners for driving innovation, enhancing efficiency, and improving product and service quality. Investing in precision can lead to the most significant rewards in this context.